Weighing modules

Silo weighing system

Agreto weighing modules

Benefits of weighing modules

- Reliable monitoring of the current level in a silo

- Monitoring quantities purchased or sold

- Timely reordering of goods

- Easy way to retrofit a silo with a scale

Application areas of weighing modules

Silos outdoors

Outside silos are exposed to wind pressure, so silo scale systems must be dimensioned to twice the load and must have reliable anti-lift-off protection to prevent the silo from falling over.

Silos indoors

All larger weighing applications require a floating load transfer from the construction to the loadcell so that tension in the construction does not negatively impact the weighing result.

Container

The silo weighing system allows the content of all types of containers to be easily weighed and monitored.

Machinery

The weighing modules can also be used to weigh any machine parts and system parts that require weight details or capacities.

The ideal version for any application

3 modules

Capacity 5t, 10t or 15t each

4 modules

Capacity 5t, 10t or 15t each

6 modules

Capacity 5t, 10t or 15t each

8 modules

Capacity 5t, 10t or 15t each

Why Agreto?

Advantages for dealers and OEM partners

- Reliable manufacturer from Austria with a professional service

- Well known in the market

- High-quality products with very low service requirements

- Instruction manuals in 25 languages

- Product individualization for OEM partners

Advantages for users

- Robust - The system is designed for heavy loads with a high safety factor

- Safe - The anti-lift-off protection is dimensioned to 100 percent of the rated load

- Easy - Can be fixed on the floor after assembly

- Practicable - The loadcell can be changed without dismantling the module

- Durable - 5 year warranty

Downloads for weighing modules

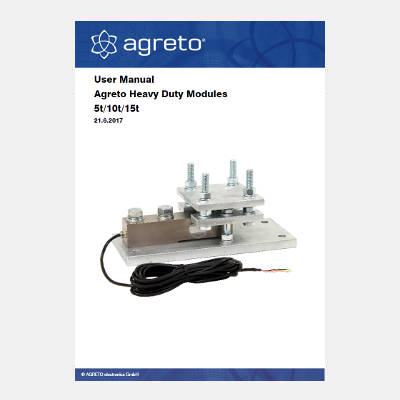

Technical data weighing modules

| Loadcell: | |

| Rated load: | 5, 10 t or 15 t per module |

| Safe overload: | 150 % |

| Accuracy: | 0,02 % |

| Full scale output: | 2 mV / V |

| Power supply: | 5 to 12 VDC |

| Operating temperature: | -35 to +70 C, -31 to +158 F |

| Protection class: | IP68 |

| Cable length: | 6 m |

| Weighing module: | |

| Material: | Hot dip galavanized steel |

| Base plate 5 t: | 380 x 150 x 20 mm (L-W-H) |

| Top plate 5 t: | 150 x 150 x 15 mm (L-W-H) |

| Total height 5 t: | 114 mm |

| Base plate 10/15 t: | 440 x 200 x 25 mm (L-W-H) |

| Top plate 10/15 t: | 200 x 200 x 15 mm (L-W-H) |

| Total height 10/15 t: | 168 mm |

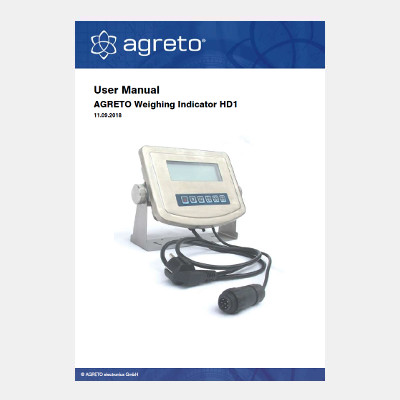

Downloads for HD1 weight indicator

Technical data HD1 weight indicator

| Material: | stainless steel |

| Weight range: | 0 to 999,999 kg / lb |

| Display: | 6-digit backlit LCD, digits height: 25 mm |

| Resolution: | 0.001 to 50 kg / lb |

| Functions: | auto zero, manual zero, zero stabilisation, summing, automatic animal mode, energy saving mode |

| Operating temperature: | -20 to +70 C, -4 to +158 F |

| Protection class: | IP67 |

| Power supply: | 110 to 230 VAC or 2 AA batteries 1.5 V |

| Dimensions (with bracket): | 258 x 178 x 58 mm (W-H-D) |

Related products

Scale kit with weighing feet

Weighbeams

Weigh beams for universal use under cattle crushes, animal weighbridges and platforms